LED outdoor display waterproof need to pay attention to what problems?

News

LED outdoor LED display waterproof need to pay attention to what problems?

1. LED outdoor display waterproof need to solve the core problems and solutions?

2. Do you know the IP waterproof grade of LED outdoor display?

3. How to choose the right IP waterproof grade for outdoor display?

Outdoor LED display is exposed to the natural environment for a long time, waterproof is really a big problem. First of all, we have to consider the common outdoor environmental factors, such as rain, humidity, temperature changes and so on. Waterproof is not only to prevent water from entering, but also to consider dustproof, because dust and particles may also affect the operation of the display.

The structure of the Outdoor LED display, the various parts may face waterproofing challenges. For example, the seams between Outdoor LED modules, at the power and signal interfaces, and the heat sink holes are all places where water can easily enter. It is necessary to ensure that these parts have adequate sealing measures, such as the use of waterproof tape, sealant and other materials.

In addition, the choice of materials is also important. Enclosure materials need to be corrosion-resistant and able to withstand acids or other corrosive elements in rainwater. At the same time, internal electronic components may need to be coated with a waterproof coating or use waterproof components, such as waterproof connectors.

There may be a conflict between heat dissipation and waterproofing. Because the LED display generates heat when operating, it needs heat sinks or fans to cool it down, but the openings may allow water to enter. This may require the design of a waterproof cooling structure, such as a labyrinth of cooling channels, which can dissipate heat and prevent water from entering directly.

The installation method will also affect the waterproof effect. For example, whether the tilt angle of the Outdoor LED display is conducive to drainage, whether the mounting frame is sufficiently sealed, and whether drainage holes are left in the installation.

There is also the issue of maintenance. Even if it is designed to be waterproof, the sealing material may deteriorate after long-term use and needs to be checked and replaced regularly. To ensure that the waterproof performance continues to be effective.

In terms of standards, IP protection level needs to be mentioned, especially IP65 or higher, which is a common waterproof and dustproof standard for outdoor equipment. Explain the specific meanings of these standards to help users understand the protective capabilities of the Outdoor LED display.

A deeper need that may not be mentioned by users is that they may want to know how to choose a qualified outdoor LED display or what details they need to pay attention to during installation to avoid future problems. Therefore, in addition to listing the problems that need to be solved, we also need to give some practical advice, such as choosing products that meet the IP rating and regular maintenance.

Finally, we answer in detail from the aspects of structural design, material selection, balance between heat dissipation and waterproofing, installation methods, maintenance and standards to comply with, to ensure that users have a comprehensive understanding of the various issues that need to be resolved for waterproofing of outdoor LED displays, and to provide practical solutions.

In the outdoor environment, LED display need to deal with rain, humidity, dust, temperature difference and other multiple challenges, waterproof design is directly related to its life and stability. The following are the core problems and solutions that need to be solved for LED outdoor display waterproofing:

the core problems and solutions that need to be solved for LED outdoor display waterproofing:

LED outdoor display waterproof need to solve the core problems and solutions?

I. Structural waterproofing problems

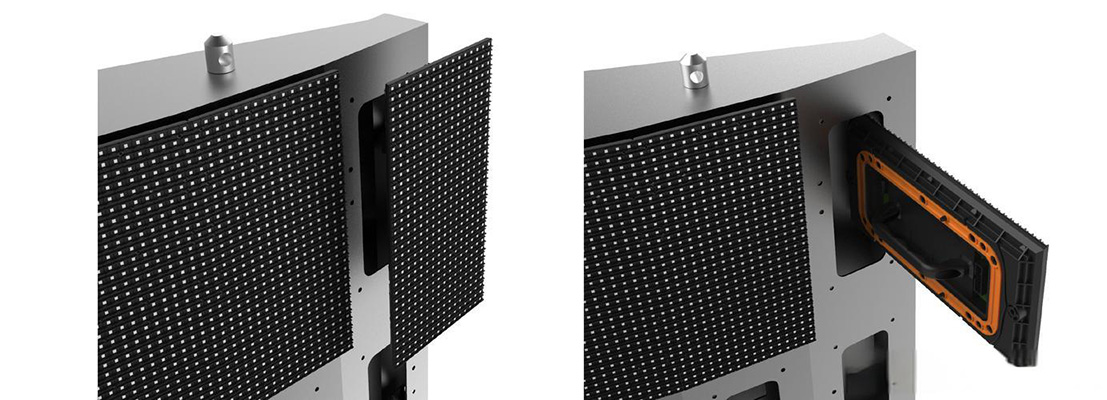

Outdoor LED module seams sealing

Problems: module splices are prone to water seepage, resulting in short circuit of the internal circuit.

Outdoor LED display waterproof Solution:

Use silicone sealing strip or waterproof glue to fill the joints.

Use IP67 grade waterproof Cabinet design to ensure that the sealing is still maintained after the LED modular splicing.

Outdoor LED Display Power and signal interface protection:

The interface is exposed to the outside, and rainwater can easily penetrate through the cables.

Outdoor LED Digital Billboard waterproof Solution:

Use waterproof connectors (such as aviation plugs) and install waterproof sleeves.

Install the connector facing downward to avoid water buildup.

Conflict between heat dissipation and waterproofing

Problem: Heat dissipation holes may become channels for water ingress.

Outdoor LED Video wall Waterproof Solution:

Adopt a “labyrinth” cooling structure to utilize the difference in air pressure to expel heat while preventing water from entering.

The use of waterproof breathable membrane (ePTFE material), allowing air circulation but blocking liquid water.

Second, the material and process issues

LED Display PCB board moisture and corrosion

Problems: moisture erosion of the circuit, triggering oxidation or short circuit.

Outdoor LED PCB surface Protection Solution:

LED PCB surface spraying three anti-paint (moisture, salt spray, mold).

The use of gold immersion process or antioxidant plating to protect the pad.

LED lamp bead protection

Problem: lamp bead gel aging leads to water vapor intrusion.

Outdoor LED lamp bead Solution:

Use epoxy resin encapsulation or silicone filled waterproof lamp beads (IP68 grade).

Increase the hydrophobic coating on the surface of the lamp to reduce the adhesion of water droplets.

Shell weathering

problems: UV rays, temperature differences lead to shell deformation or cracking.

Outdoor LED Cabinet Solution:

Use die-cast aluminum case or high impact polycarbonate (PC) material.

Add UV stabilizer to prevent material aging.

Environmental Adaptive Design

Drainage and Water Resistance

Problem: Rainwater accumulates on the surface or inside the screen.

Solution:

The outdoor LED screen is tilted 3-5° as a whole to utilize gravity for natural drainage.

The bottom of the outdoor led cabinet is designed with deflector slots and drainage holes.

Temperature extremes: Expansion of icing at low temperatures or softening of colloids at high temperatures.

Solution:

Use wide temperature range materials (-40℃~85℃ resistant).

Add internal temperature control system to automatically adjust heat dissipation/heating.

Salt spray corrosion (coastal area)

problem: Sea breeze and salt accelerate the corrosion of metal parts.

Solution:

Stainless steel screws + anodized aluminum frame.

Clean and spray rust inhibitor regularly.

Fourth, the test and certification standards

IP protection level verification of outdoor LED screens need to meet at least IP65 (anti-spray, dust), the harsh environment requires IP67 (short-term immersion).

Test methods: spray test (IPX5: 12.5L/min water pressure spray), immersion test (IPX7: 1 meter water depth for 30 minutes).

Aging and reliability test

high temperature and high humidity test (85℃/85% RH, 1000 hours).

Cold and thermal shock test (-40℃↔70℃ cycle).

V. Maintenance and Failure Prevention

Regularly check whether the key sealing rubber strip is aging and cracking.

Drainage holes are blocked (especially in dusty environment).

Emergency measures

Immediately disconnect the power after heavy rain and blow dry the interior with compressed air.

When local black screen is found, prioritize to check whether the power connector is water ingress.

Industry application cases

Stadium: Curved screen adopts double-layer waterproof structure, inner sealed box + outer hydrophobic membrane.

Highway screen: equipped with heating demisting function to prevent low-temperature condensation.

Seaside advertising screen: full stainless steel frame + ceramic coated PCB, salt spray resistance life increased by 50%.

Through systematic waterproof design, LED outdoor display can achieve 5-10 years of stable operation. When choosing products, you need to focus on the three core indicators of IP rating, material process, heat dissipation design, and regular maintenance to cope with environmental changes.

18027665203

18027665203